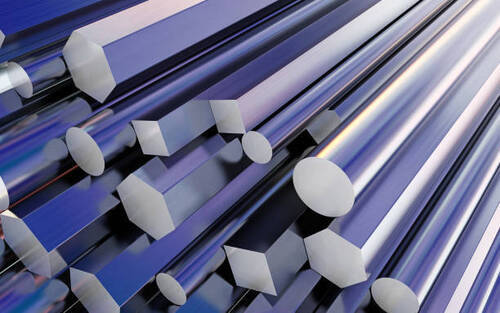

Super Duplex Steel Round Bar S32750

Price 450 INR/ Number

Super Duplex Steel Round Bar S32750 Specification

- Processing

- Peeled, Turned, Straightened

- Type

- Round Bar

- Diameter

- 6 mm to 350 mm

- Specific Use

- High Corrosion Resistance and Strength Requirements

- Technique

- Hot Rolled, Cold Drawn, Forged

- Material

- Super Duplex Steel S32750

- Finish

- Bright, Black, Polished

- Length

- 100 mm to 6000 mm or as required

- Application

- Oil & Gas Industry, Chemical Processing, Marine Applications, Power Plant Construction

- Standard

- ASTM A276, ASTM A479, UNS S32750

- Tolerance

- H9, H10, H11 or as per request

- Grade

- S32750

- Magnetic Properties

- Magnetic

- Density

- 7.8 g/cm³

- Elongation

- > 15%

- Hardness

- Max 300 HB

- Corrosion Resistance

- Excellent to pitting and crevice corrosion (PREN > 40)

- Tensile Strength

- > 800 MPa

- Yield Strength

- >= 550 MPa

- Heat Treatment

- Solution Annealed

- Packaging

- Export-worthy wooden cases or as per requirement

About Super Duplex Steel Round Bar S32750

Super Duplex Steel F53 Square Bar, UNS S32750 F53 Flat Bar, UNS S32750 F53 Forged Bars Suppliers in India. Super Duplex Hexagon Bars, Super Duplex F53 UNS S32750 Round Bars, F53 Hex Bar Exporter Leading Manufacturers. All India metal corporation is one of the largest exporter, manufacturer and supplier of Super Duplex Steel UNS 32750 Round Bars in India. Meanwhile, we offer different types of these bars such as Super Duplex Steel UNS 32750 Bright Bars, Super Duplex Steel UNS 32750 Hex Bars, Super Duplex Steel UNS 32750 Black Bars, Super Duplex Steel UNS 32750 Flat Bars, Super Duplex Steel UNS 32750 Billets Bars, and Super Duplex Steel UNS 32750 Forged Bars.Superior Corrosion Resistance for Demanding Environments

Engineered with a high PREN value exceeding 40, Super Duplex Steel S32750 round bars deliver robust resistance to pitting and crevice corrosion. This property ensures dependable performance in aggressive chemical processing, marine, and oil & gas environments, where ordinary steels often succumb to corrosion.

Exceptional Strength Coupled with Versatility

S32750 round bars boast a yield strength of at least 550 MPa and tensile strength above 800 MPa, providing structural assurance in critical applications. They are available in finishes like bright, black, and polished, and can be processed via peeling, turning, and straightening to match specific project needs.

Meeting Stringent Industry Standards

Conforming to ASTM A276, ASTM A479, and UNS S32750, these round bars embody global benchmarks for quality and reliability. Their precise tolerances (H9, H10, H11, or as required) and customizable lengths and diameters make them suitable for a wide spectrum of industrial uses.

FAQ's of Super Duplex Steel Round Bar S32750:

Q: How is Super Duplex Steel S32750 round bar processed for quality and consistency?

A: Super Duplex Steel S32750 round bars undergo hot rolling, cold drawing, and forging processes. They are finished through methods such as peeling, turning, and straightening, followed by solution annealing to optimize strength and corrosion resistance, ensuring uniform quality and performance.Q: What makes S32750 round bars highly resistant to corrosion in marine and chemical environments?

A: S32750 contains high levels of chromium, molybdenum, and nitrogen, resulting in a Pitting Resistance Equivalent Number (PREN) greater than 40. This composition ensures exceptional resistance to pitting and crevice corrosion, even in highly aggressive and chloride-rich environments.Q: Where are Super Duplex S32750 round bars typically used?

A: These round bars are extensively utilized in applications requiring both high corrosion resistance and mechanical strength, including the oil & gas industry, marine structures, chemical processing plants, and power plant construction, where reliability is critical.Q: What is the benefit of the solution annealed heat treatment for S32750 round bars?

A: Solution annealing enhances the microstructure of S32750 round bars, improving their strength, toughness, and overall corrosion resistance. This treatment ensures the bars meet strict mechanical and durability criteria required in demanding applications.Q: When should I choose a Super Duplex Steel S32750 round bar over standard stainless steel?

A: Choose S32750 round bars when your application demands superior strength, higher resistance to localized corrosion, and longer service life in harsh environments-such as offshore platforms or chemical plants-where standard stainless steel may not perform adequately.Q: What packaging options are available for safe transport of S32750 round bars?

A: Super Duplex S32750 round bars are typically packaged in export-worthy wooden cases, but packaging can also be customized according to specific shipping and handling requirements to ensure the products remain protected during transit.Q: How does the magnetic property of S32750 round bars affect their usage?

A: S32750 is magnetic due to its duplex structure, which can be a key factor in certain applications that require magnetic detection or separation, while still ensuring the bar's superior mechanical and corrosion-resistant properties.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Duplex Steel Round Bar Category

Duplex Steel Wire

Price 500 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Material : Duplex Steel

Finish : Bright, Matte

Standard : ASTM, ASME, DIN, EN

Diameter : 0.10 mm to 12 mm

Duplex Steel 2205 Round Bar / Rod

Price 300.0 INR / Kilograms

Minimum Order Quantity : 5 Kilograms

Material : Steel

Finish : Black, Bright Polished

Standard : ASTM A276, A479 / ASME SA276, SA479, ASTM A789 / A789M & ASTM A928 / A928M

Stainless Steel Round Bar

Price 300.00 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Material : Stainless Steel ROUND BAR

Finish : Available in various surface finishes including polished, rough turned, or centerless ground, providing versatility for different applications.

Standard : 304/316

Diameter : 4 MM TO 150 MM DIA Millimeter (mm)

Super Duplex S32760 Round Bar

Price 700 INR / Number

Minimum Order Quantity : 5 Kilograms

Material : Super Duplex Stainless Steel S32760

Finish : Bright, Black, Polished, Peeled

Standard : ASTM A276, ASTM A479, UNS S32760

Diameter : 5 mm to 500 mm

GST : 27AALHA0224K1ZI

|

METAL VISION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry