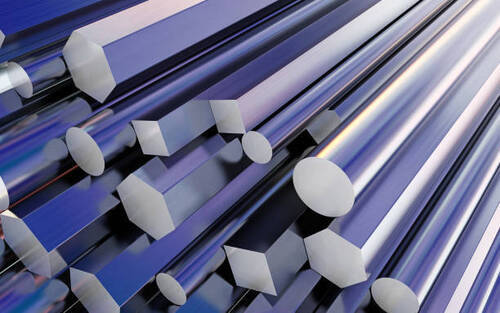

Duplex UNS S31803 F51 Round Bars / Rods

Price 300 INR/ Number

Duplex UNS S31803 F51 Round Bars / Rods Specification

- Processing

- Peeled, Drawn, Turned, Ground

- Grade

- Duplex S31803 (F51)

- Type

- Round Bars / Rods

- Application

- Oil & Gas, Petrochemical, Chemical Processing, Marine Engineering, Heat Exchangers, Pulp & Paper Industry

- Tolerance

- H8, H9, H10, or as specified

- Specific Use

- Pressure Vessel Components, Shafts, Valves, Fasteners

- Length

- 2 to 6 meters or custom cut lengths

- Finish

- Bright, Black, Polished

- Technique

- Hot Rolled, Cold Drawn, Forged

- Diameter

- 6mm to 300mm

- Material

- Duplex Stainless Steel UNS S31803 / F51

- Standard

- ASTM A276, ASTM A479, ASME SA276, SA479

- Elongation

- 25%

- Welding

- Suitable for standard welding methods

- Heat Treatment

- Solution Annealed

- Corrosion Resistance

- Excellent pitting and crevice corrosion resistance

- Hardness

- 290 HB

- Form

- Solid Bar / Rod

- Tensile Strength

- 620 MPa

- Packaging

- Standard export packing in bundles or wooden boxes

- Density

- 7.8 g/cm

- Magnetic Properties

- Slightly magnetic due to duplex structure

- Surface Condition

- Free of scale and defects

- Temperature Range

- -50C to +300C

- Yield Strength

- 450 MPa

About Duplex UNS S31803 F51 Round Bars / Rods

UNS S31803 F51 Round BarsDuplex Steel UNS S31803 F51 Hexagon Bars, UNS S31803 F51 Forged Bars, Duplex F51 Round Bars Suppliers in India. UNS S31803 F51 Flat Bar, UNS S31803 F51 Hex Bar Exporter, Duplex Steel F51 Square Bar Leading Manufacturers. Meanwhile, we offer different types of these bars such as Duplex Steel UNS S31803 Bright Bars, Duplex Steel UNS S31803 Hex Bars, Duplex Steel UNS S31803 Black Bars, Duplex Steel UNS S31803 Flat Bars, Duplex Steel UNS S31803 Billets Bars, and Duplex Steel UNS S31803 Forged Bars. Our Duplex Steel UNS S31803 Rods are accessible to our valuable customers in different range of diameters, wall thicknesses and sizes in customized form and also at quite affordable rates.ASTM A276, A479 UNS S31803 F51 Round Bars Specification

Specification : ASTM, ASME and API

Standard Specification : ASTM A182, ASTM A276, ASTM A479

Size : 6 mm to 120 mm.

Thickness : 100 to 6000 mm Length

Finish : Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Our UNS S31803 F51 Round Bars conforms to NACE MR0175/ISO 15156

Exceptional Mechanical Strength and Durability

Duplex UNS S31803 F51 Round Bars/Rods are engineered to deliver superior mechanical performance, combining a high yield strength (450 MPa) and tensile strength (620 MPa) with robust elongation properties (25%). These attributes ensure long-term durability and optimal performance even in high-pressure environments, which is why they are widely chosen for pressure vessel components, shafts, and industrial fasteners.

Outstanding Corrosion Resistance

Benefit from excellent resistance to pitting and crevice corrosion, allowing these duplex stainless steel bars and rods to thrive in aggressive environments like marine engineering, chemical processing, and oil & gas sectors. Their surface is solution annealed and meticulously finished, providing additional protection and ensuring reliability in harsh service conditions.

Versatile Applications Across Industries

With multiple form factors, finishes, and processing techniques available, Duplex UNS S31803 F51 Round Bars/Rods are suitable for diverse applications-from heat exchangers and valves to marine structural components and the pulp & paper industry. They are offered in tailored lengths and diameters to meet specific project and operational requirements.

FAQ's of Duplex UNS S31803 F51 Round Bars / Rods:

Q: How are Duplex UNS S31803 F51 Round Bars and Rods manufactured?

A: These round bars and rods are produced using techniques such as hot rolling, cold drawing, or forging. They undergo solution annealing to achieve the desired microstructure and are further processed by peeling, drawing, turning, or grinding, depending on the finish required.Q: What benefits do Duplex S31803 (F51) bars offer compared to conventional stainless steel rods?

A: Duplex S31803 (F51) bars offer a balanced combination of high strength (yield strength 450 MPa), excellent corrosion resistance-especially against pitting and crevice corrosion-and improved elongation, making them more durable and reliable for critical applications than many standard austenitic stainless steels.Q: When should Duplex UNS S31803 F51 bars be used in industrial projects?

A: These bars and rods are ideal when you require components with both high mechanical strength and superior resistance to aggressive environments-such as pressure vessels, shafts, fasteners, marine equipment, or components exposed to corrosive media in the chemical and oil & gas industries.Q: Where can Duplex S31803 (F51) round bars and rods be sourced from in India?

A: They are available through reputable manufacturers, exporters, importers, suppliers, traders, and wholesalers across India, often supplied with standard export packing in bundles or wooden boxes to ensure safe delivery.Q: How can Duplex UNS S31803 F51 rods be joined or welded?

A: These rods are suitable for standard welding methods. Their duplex structure provides slight magnetism but does not impede welding, allowing for strong, reliable joints using appropriate filler materials and techniques tailored for duplex stainless steels.Q: What is the temperature range for safe usage of Duplex S31803 (F51) round bars and rods?

A: They maintain their excellent mechanical and corrosion resistance properties across a broad temperature spectrum, typically from -50C to +300C, making them versatile in a range of industrial applications.Q: What surface finishes and diameters are available for Duplex UNS S31803 F51 round bars?

A: Available surface finishes include bright, black, and polished, with processing options such as peeled, drawn, turned, or ground. Diameters range from 6mm to 300mm, accommodating various industry requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Duplex Steel Round Bar Category

Duplex Steel Wire

Price 500 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Material : Duplex Steel

Diameter : 0.10 mm to 12 mm

Standard : ASTM, ASME, DIN, EN

Finish : Bright, Matte

Stainless Steel Round Bar

Price 300.00 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Material : Stainless Steel ROUND BAR

Diameter : 4 MM TO 150 MM DIA Millimeter (mm)

Standard : 304/316

Finish : Available in various surface finishes including polished, rough turned, or centerless ground, providing versatility for different applications.

Duplex Steel 2205 Round Bar / Rod

Price 300.0 INR / Kilograms

Minimum Order Quantity : 5 Kilograms

Material : Steel

Standard : ASTM A276, A479 / ASME SA276, SA479, ASTM A789 / A789M & ASTM A928 / A928M

Finish : Black, Bright Polished

Super Duplex Steel Round Bar S32750

Price 450 INR / Number

Minimum Order Quantity : 5 Kilograms

Material : Super Duplex Steel S32750

Diameter : 6 mm to 350 mm

Standard : ASTM A276, ASTM A479, UNS S32750

Finish : Bright, Black, Polished

GST : 27AALHA0224K1ZI

|

METAL VISION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry