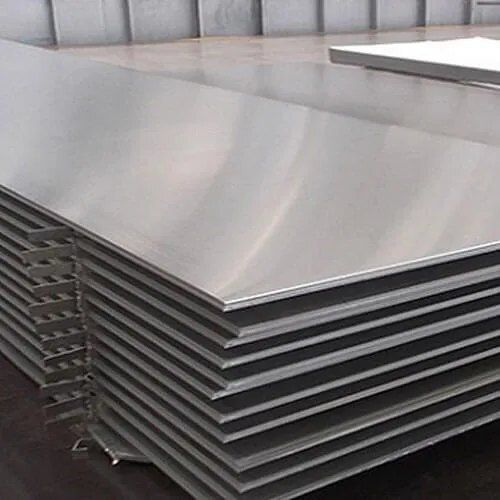

Nickel 200 Sheet / Plate / Coil

Price 900 INR/ Number

MOQ : 5 Kilograms

Nickel 200 Sheet / Plate / Coil Specification

- Product Type

- Nickel 200 Sheet / Plate / Coil

- Shape

- Sheet, Plate, Coil

- Elongation

- Elongation at break: 40%

- Strength

- Tensile Strength: 450 MPa (approx.)

- Hardness

- Rockwell B60 (approx.)

- Resistance

- Excellent resistance to acids, alkalis, and reducing environments

- Grade

- Nickel 200

- Melting Range

- 1435C - 1446C

- Density

- 8.89 Gram per cubic centimeter(g/cm3)

- Chemical Composition

- Nickel (Ni) 99.0%

- Application

- Chemical processing, Marine, Food processing, Aerospace, Power generation

- Color

- Silvery-grey

- Packaging

- Standard export packing, wooden box, pallet, or as required

- Corrosion Resistance

- Highly resistant to corrosion in neutral, alkaline and acidic environments

- Surface Quality

- Smooth, free from scale and defects

- Electrical Conductivity

- Approximately 22% IACS

- Magnetic Permeability

- Non-magnetic

- Thermal Conductivity

- Approximately 90 W/m·K

- Finish

- Hot Rolled, Cold Rolled, Annealed

- Thickness Range

- 0.5 mm to 50 mm

- Length Range

- As per requirement or up to 6000 mm

- Width Range

- 100 mm to 2500 mm

- Standard

- ASTM B162, ASTM B160

About Nickel 200 Sheet / Plate / Coil

Nickel 200 Plates, JIS NW 2200 Plate, Nickel Alloy 200 Coils, Alloy 200 Sheets, Nickel UNS N02200 Plates, Nickel 200 Circle, ASME SB 162 Nickel 200 Plate, 200 Nickel Hot Rolled Plates Supplier in Mumbai, India. Distributors Of ASME SB162 Nickel 200 Coils, 200 Nickel Plate Stockholder, 200 Nickel Polished Cold Drawn Plates, Nickel GOST ????-2 Strips Stockist, Manufacturer.Precision Manufacturing & Quality Standards

Nickel 200 sheets, plates, and coils are manufactured conforming to ASTM B162 and ASTM B160, ensuring reliable quality for industrial applications. Available in various finishes and customizable dimensions, each piece undergoes rigorous inspection to provide smooth surfaces free from scale and defects. Standard export packaging enhances safety and facilitates global distribution.

Exceptional Corrosion and Chemical Resistance

Renowned for its remarkable resistance to acids, alkalis, and reducing environments, Nickel 200 is the preferred choice for industries like chemical processing and marine engineering. Its silvery-grey appearance denotes purity and strength, while the high nickel content provides enduring protection, even in harsh and demanding environments.

Diverse Applications and Process Flexibility

With forms available as sheets, plates, and coils, Nickel 200 meets the requirements of diverse sectors. Its superb mechanical properties-such as 450 MPa tensile strength, 40% elongation, and high melting range-make it suitable for food processing, power generation, and even aerospace. The material accommodates custom length specifications up to 6000 mm, offering flexibility for varied project needs.

FAQ's of Nickel 200 Sheet / Plate / Coil:

Q: How is Nickel 200 Sheet/Plate/Coil typically used in industry?

A: Nickel 200 Sheet/Plate/Coil serves a broad range of applications due to its corrosion resistance and mechanical strength. Common uses include chemical processing equipment, marine hardware, food processing plants, aerospace components, and power generation facilities.Q: What are the primary benefits of choosing Nickel 200 for corrosion resistance?

A: Nickel 200 offers excellent resistance to corrosion in neutral, alkaline, and acidic environments, making it ideal for harsh chemical and marine conditions. Its high nickel content ( 99%) ensures durability and longevity in demanding settings.Q: What surface finishes are available for Nickel 200 products?

A: Nickel 200 is supplied in hot rolled, cold rolled, or annealed finishes. All surfaces are smooth, free from scale and defects, ensuring both functionality and appearance meet strict quality requirements.Q: What is the typical process for ordering Nickel 200 Sheet/Plate/Coil?

A: Customers can specify dimensions (thickness, width, length) within the available range and select the desired finish. Suppliers offer standard export packaging such as wooden boxes or pallets, tailored to shipping needs. Custom lengths up to 6000 mm are accommodated.Q: Where is Nickel 200 commonly manufactured and exported from?

A: Nickel 200 products are manufactured, supplied, and exported globally, with India being a key hub for exporters, manufacturers, and traders serving various industries worldwide.Q: What are the key mechanical properties of Nickel 200 that support its application in critical environments?

A: Nickel 200 provides a tensile strength of approximately 450 MPa, Rockwell hardness B60, and 40% elongation at break. These properties, together with its non-magnetic behavior and high thermal conductivity, make it ideal for tough and high-performance applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Nickel Alloy Products Category

Nickel 201 Round Bar

Price 1000 INR / Number

Minimum Order Quantity : 5 Kilograms

Product Type : Other, Nickel 201 Round Bar

Grade : Nickel 201

Shape : Other, Round

Nickel Alloy Pipe Alloy-20

Price 2500 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Product Type : Other, Nickel Alloy Pipe

Grade : Alloy 20 (UNS N08020)

Shape : Other, Round/Seamless/Welded Pipe

Hastelloy Plates

Price Range 2500.00 - 6000.00 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Product Type : Nickel Alloy

Grade : Industrial

Shape : Square

Copper Alloys

Price Range 2500.00 - 6000.00 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Product Type : Nickel Alloy

Grade : Industrial

METAL VISION

GST : 27AALHA0224K1ZI

GST : 27AALHA0224K1ZI

512, 5 TH FLOOR, PAREKH MARKET, NEAR OPERA HOUSE, CHARNI ROAD STATION,Mumbai - 400004, Maharashtra, India

Phone :08045803979

|

METAL VISION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry