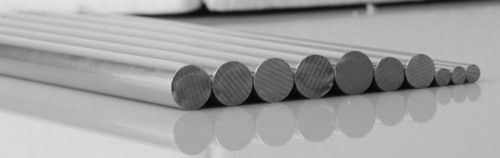

Monel K500 Round Bar

Price 1200 INR/ Number

Monel K500 Round Bar Specification

- Tolerance

- H9, H11, H13, as per standard

- Finish

- Bright, Black, Polished

- Processing

- Annealed, Hardened & Tempered

- Type

- Round Bar

- Application

- Chemical Processing, Marine Engineering, Oil & Gas, Aerospace

- Grade

- K500

- Specific Use

- High strength applications, corrosion-resistant parts

- Length

- Random, Cut Length, up to 6 meters

- Material

- Monel K500

- Diameter

- 6 mm to 300 mm

- Technique

- Hot Rolled / Cold Drawn

- Standard

- ASTM B865, ASME SB865

- Packaging

- Standard export packaging, customized as per requirement

- Heat Treatment

- Aging, Solution Annealed

- Tensile Strength

- 965 MPa min

- Yield Strength

- 690 MPa min

- Corrosion Resistance

- Excellent in marine and chemical environments

- Elongation

- 20% min

- Surface Condition

- Smooth, free from scale

- Hardness

- Rockwell B100 - C35

- Density

- 8.44 g/cm³

- Magnetic Properties

- Non-magnetic

- Availability

- Ex-stock & Make to order

About Monel K500 Round Bar

MONEL ALLOY K500 Bar, ASTM B865 Monel K500 Round Bars, Monel UNS N05500 Bright Bar, K500 Monel Triangular Bar, Monel K500 Round Bar, Monel Alloy K500 Rods Suppliers and Dealer in Mumbai, India. Monel K500 Round Bar, Suppliers of ASTM B865 Monel K500 Hex Bar, K500 Monel Alloy Forged Bars Exporter, Alloy K500 Square Bar, Monel WERKSTOFF NR. 2.4375 Round Bars Manufacturer in India. Monel Alloy K500 Flat Bar, Monel K500 Hexagonal Bar, Hot Rolled Monel K500 Round Bar, Monel K500 Cold Drawn Round Bar, K500 Monel Polished Bar, Specialist Distributor of ASTM B865 Alloy K500 Threaded Bar, K500 Alloy Black Bar Exporter in India.Exceptional Strength and Corrosion Resistance

Monel K500 Round Bars deliver a unique combination of high mechanical strength and superior resistance to corrosion in harsh marine and chemical settings. Their robust properties stem from a nickel-copper alloy composition, enhanced by precise heat treatment processes like aging and solution annealing. These characteristics make them highly sought after for critical applications demanding long-term reliability.

Versatile Industrial Applications

These round bars are integral to industries such as marine engineering, chemical processing, aerospace, and oil & gas. Their non-magnetic nature, excellent surface condition, and customizable tolerances allow them to be tailored for specialized needs-ranging from high-strength components to corrosion-resistant parts in demanding settings.

Flexible Sizing, Packaging, and Availability

Monel K500 bars are available in diameters from 6 mm to 300 mm and lengths up to 6 meters, with finishing options like bright, black, or polished surfaces. Packaged per export standards or customized as required, they are readily accessible as ex-stock or can be made to order, ensuring prompt and flexible supply to global clients.

FAQ's of Monel K500 Round Bar:

Q: How is Monel K500 Round Bar manufactured and finished?

A: Monel K500 Round Bars are produced via hot rolling or cold drawing techniques, followed by heat treatments such as solution annealing and aging. They are available in bright, black, or polished finishes and are processed to achieve smooth, scale-free surfaces with tolerances like H9, H11, or H13 as per your needs.Q: What benefits does Monel K500 offer in marine and chemical environments?

A: This alloy provides excellent corrosion resistance even in aggressive marine and chemical settings, ensuring longevity and reduced maintenance in submerged, corrosive, or high-salinity applications-making it a preferred choice for critical infrastructure and parts.Q: When should Monel K500 Round Bars be chosen over other alloys?

A: Select Monel K500 when high strength, excellent corrosion resistance, and non-magnetic properties are required, especially for use in demanding environments such as offshore platforms, chemical plants, and aerospace assemblies.Q: Where can Monel K500 Round Bar be used most effectively?

A: Monel K500 Round Bars are ideally suited for use in chemical processing, marine engineering, oil & gas industries, and aerospace applications, particularly where high-strength, corrosion-resistant performance is mandatory.Q: What applications benefit from the unique properties of Monel K500?

A: Parts that require both mechanical durability and corrosion resistance-like shafts, fasteners, valves, pumps, and gears-benefit greatly from Monel K500, especially in environments where exposure to seawater or chemicals is unavoidable.Q: How is Monel K500 Round Bar supplied and packaged?

A: These bars are available both as ex-stock for urgent requirements and on a make-to-order basis for custom specifications. Packaging follows standard export procedures and can be customized to meet specific client and transit needs.Q: What standards and sizes are offered for Monel K500 Round Bar?

A: Monel K500 Round Bars conform to ASTM B865 and ASME SB865 standards, available in diameters from 6 mm up to 300 mm and in various cut or random lengths up to 6 meters to satisfy diverse project requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Monel Round Bar Category

Monel 400 Round Bar

Minimum Order Quantity : 10 Kilograms

Application : Chemical Processing, Marine Engineering, Oil and Gas, Heat Exchangers

Type : Round Bar

Length : 100 mm to 6000 mm or custom cut

Material : Monel 400

EN 8 Round Bar

Price 60 INR / Number

Minimum Order Quantity : 5 Kilograms

Application : General Engineering, Automobile, Construction, Shafts, Axles, and Machinery Parts

Type : Round Bar

Length : 1000 mm to 6000 mm (custom lengths available)

Material : EN 8 Carbon Steel

Nickel 200 Round Bar

Price 900 INR / Number

Minimum Order Quantity : 5 Kilograms

Application : Chemical Processing, Food Processing, Marine, Aerospace, Power Generation

Type : Round Bar

Length : 1 meter to 6 meters (custom cut available)

Material : Nickel 200

Invar 36 Round Bar

Price 1500 INR / Number

Minimum Order Quantity : 5 Kilograms

Application : Precision instruments, aerospace, cryogenic components, scientific devices

Type : Round Bar

Length : Up to 6000 mm or custom cut

Material : Invar 36 (NickelIron Alloy)

GST : 27AALHA0224K1ZI

|

METAL VISION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry