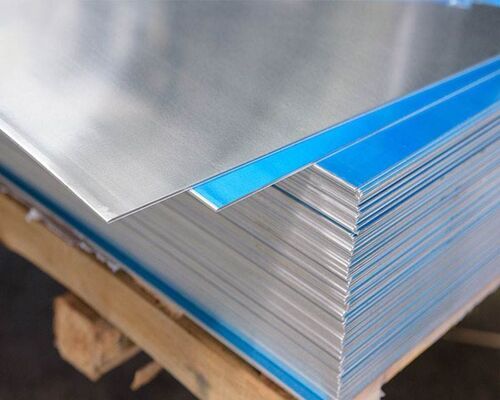

Aluminum 1050 Sheet / Plate / Coil

Price 280 INR/ Number

Aluminum 1050 Sheet / Plate / Coil Specification

- Material Grade

- 1050

- Fabrication Process

- Cold rolled, hot rolled

- Corrosion Resistant

- Excellent resistance to corrosion

- Size

- Standard and custom sizes

- Finish

- Smooth, mill finish

- Width

- Up to 1550 mm

- Thickness

- 0.2 mm to 6 mm

- Cross Dimension

- As specified

- Outer Diameter

- Up to 1500 mm for coil

- Diameter

- Applicable for coil; up to 1500 mm

- Length

- Custom or standard; typically up to 6000 mm

- Usage & Applications

- General fabrication, chemical equipment, food industry, reflectors, architectural, electrical, signage

- Temper

- O, H12, H14, H16, H18, H22, H24, H26, H28

- Features

- High purity, good reflectivity, excellent formability, ductility

- Material

- Pure Aluminum (99.5% min.)

- Product Type

- Sheet, Plate, Coil

- Shape

- Sheet, plate, coil

- Strength

- Low to moderate strength (Yield Strength: ~20-40 MPa)

- Hardness

- Brinell Hardness: ~35 HB

- Alloy

- Aluminum 1050

- Grade

- 1050

- Surface Treatment

- Mill finish, anodized, coated

- Dimension (L*W*H)

- Custom or standard dimensions (e.g. 1000x2000x1 mm)

- Color

- Silver/Metallic

- Melting Point

- 650°C

- Machinability

- Easy to machine and cut

- Weight

- Varies as per dimension and thickness

- Density

- 2.71 g/cm³

- Elongation at Break

- ~35%

- Packing Type

- Wooden cases or pallets

- Tensile Strength

- 60 MPa - 100 MPa

- Recyclable

- 100% recyclable

- Conductivity

- High electrical conductivity (about 59.6% IACS)

- Formability

- Excellent

About Aluminum 1050 Sheet / Plate / Coil

Al Alloy 1050 Plates,Aluminum 1050 Plates, ASTM B209 Aluminium 1050 Plates, Aluminium Alloy 1050 Plates, Aluminium 1050 Plates Stockist in Mumbai, India.ASME SB 209 Aluminium 1050 Plates, Aluminum Alloy 1050 Hot Rolled Plate, Aluminium 1050 Chequered Plates, Aluminium 1050 Plates Stockist in Mumbai, India.Aluminium 1050 CR Plate, Aluminium 1050 Cold Rolled Plate,Aluminium 1050 Industrial Plates, Aluminium 1050 Sheet, Aluminium 1050 Plates Supplier in Mumbai, India.Aluminium UNS A91050 Hot Rolled Plate | Aluminum 1050 Hot Rolled Plates | Aluminum 1050 HR Plates | Aluminium 1050 Hot Rolled Plate Stockist | Aluminium 1050 Hot Rolled Plates | Aluminum 1050 Hot Rolled Plate Stockholder in India | Aluminum 1050 Hot Rolled Plates Supplier in Mumbai, India | Al 1050 Hot Rolled PlateSpecifications: ASTM B209 / ASME SB209

Temper: O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851

Thickness: 0.2300mm

Width: 5002500mm

Length: 50010000mm

Surface: Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc.

Finish: Mill, Customer specific finish

Aluminum Sheet/ Plate Coating: PVC Coated, Color Coated, Polyester, Fluorocarbon, polyurethane and epoxy coating

Type: Hot-Rolled (HR) / Cold-Rolled (CR) Sheet / Plates/ Strips/ Coils / Chequered Plates

Aluminium 1050 Plates Equivalent GradesExceptional Electrical Conductivity

Aluminum 1050 offers high electrical conductivity, rated at approximately 59.6% IACS, making it an excellent choice for electrical and electronic applications. Its purity and metallurgical stability guarantee consistent performance, whether utilized in wiring, busbars, or electronic reflectors. This property, combined with ease of fabrication, serves industries requiring reliable conduction and lightweight material solutions.

Versatile Fabrication and Formability

Engineered for easy forming and adaptability, Aluminum 1050 stands out due to its exceptional formability and ductility. Thanks to its low to moderate strength and high elongation rate, it can be cold or hot rolled and manufactured in various shapes including sheets, plates, and coils. Its surface finish can be customized for both basic and decorative needs, supporting diverse application requirements.

Corrosion Resistance and Sustainability

Aluminum 1050 exhibits outstanding resistance to corrosion, making it suitable for environments exposed to chemicals, food products, and outdoor conditions. Its full recyclability supports sustainability goals, and its lightweight nature further reduces transportation and installation costs. Packing options like wooden cases and pallets ensure safe handling and delivery to any location.

FAQ's of Aluminum 1050 Sheet / Plate / Coil:

Q: How is Aluminum 1050 sheet, plate, or coil typically manufactured?

A: Aluminum 1050 products are manufactured by cold or hot rolling pure aluminum ingots. This process controls thickness (typically 0.2 mm to 6 mm) and produces sheets, plates, or coils in various standard and custom dimensions. Surface finishing-such as mill finish, anodizing, or coating-enhances functional and aesthetic properties.Q: What are the main benefits of using Aluminum 1050 in electrical applications?

A: The primary benefit is its high electrical conductivity (approximately 59.6% IACS), which makes it ideal for wiring, busbars, and reflectors. Additionally, its excellent formability and corrosion resistance ensure a long service life and adaptability in diverse environments.Q: When should I choose Aluminum 1050 over other aluminum alloys?

A: Choose Aluminum 1050 for projects requiring high purity, superior corrosion resistance, and easy formability over high mechanical strength. It's particularly suitable for electrical, chemical, or food-processing equipment, as well as applications where ductility or reflectivity is important.Q: Where are Aluminum 1050 sheets and coils commonly used?

A: These materials are widely used in the electrical industry, architectural decoration, food processing, chemical equipment, signage, and as reflectors in lighting and solar applications, thanks to their purity, ease of fabrication, and excellent conductivity.Q: What packing options are available for shipping Aluminum 1050 products?

A: Aluminum 1050 sheets, plates, and coils can be packed in sturdy wooden cases or on wooden pallets. This ensures the material remains undamaged in transit and makes handling and storage more secure, especially for export or long-distance shipping.Q: How does the recyclability of Aluminum 1050 benefit industries?

A: Aluminum 1050 is 100% recyclable, enabling sustainable manufacturing practices. Recycling aluminum reduces environmental impact, conserves energy, and supports circular economy initiatives, making it a preferred choice for eco-conscious businesses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminum Category

Aluminium Plate 5052

Price 300 INR / Number

Minimum Order Quantity : 5 Kilograms

Thickness : 0.5 mm to 100 mm

Size : Standard & custom sizes

Shape : Other, Rectangular, Square

Surface Treatment : Mill Finish

Aluminium 5052 Sheet / Plate / Coil

Price 360 INR / Number

Minimum Order Quantity : 5 Kilograms

Thickness : 0.2 mm 200 mm

Size : Various sizes available

Shape : Other, Sheet, Plate, Coil

Surface Treatment : Other, Mill Finish, Anodized, Coated

Aluminum Flats 6061 T6

Minimum Order Quantity : 10 Kilograms

Thickness : Varies Millimeter (mm)

Size : Custom sizes available

Shape : Flat

Surface Treatment : Mill Finish

Aluminium 6061 Rod

Price 10000.0 INR / Kilograms

Minimum Order Quantity : 5 Kilograms

Thickness : 50 mm to 6000 mm Millimeter (mm)

Size : 0.1mm 800mm

Shape : Round

Surface Treatment : Other

GST : 27AALHA0224K1ZI

|

METAL VISION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry