Aluminium 6061 Sheet / Plate / Coil

Price 323 INR/ Number

Aluminium 6061 Sheet / Plate / Coil Specification

- Material

- Aluminium

- Features

- High strength, Good weldability, Excellent machinability, Lightweight, Corrosion resistant

- Fabrication Process

- Cold Rolled / Hot Rolled / Extruded

- Diameter

- N/A for sheets/plates; applicable for coils as inner/outer diameter

- Width

- 1000 mm, 1250 mm, 1500 mm, or custom options

- Temper

- T6 / T651 / O / F / H112 (various options available)

- Outer Diameter

- As per coil specification

- Size

- Customized / Standard (4ft x 8ft, etc.)

- Corrosion Resistant

- Yes

- Material Grade

- 6061

- Finish

- Mill / Brushed / Anodized

- Length

- Standard or customized (up to 6000 mm or more)

- Usage & Applications

- Automotive, Aerospace, Marine, Transport, Structural, Fabrication, Construction

- Thickness

- 0.5 mm to 150 mm (or custom)

- Product Type

- Sheet / Plate / Coil

- Shape

- Sheet, Plate, Coil

- Strength

- Medium to High

- Hardness

- 95 HB (approx.)

- Alloy

- 6061

- Grade

- Aluminium 6061

- Surface Treatment

- Mill Finish, Anodized, Brushed

- Dimension (L*W*H)

- Custom as per requirements / standard sizes

- Color

- Silver / Aluminium Grey

- Electrical Conductivity

- 40% IACS

- Yield Strength

- 110-241 MPa

- Standard

- ASTM B209, EN573, EN485

- Tensile Strength

- 180-290 MPa (depending on temper)

- Packaging

- Standard export worthy packaging, wooden pallets, waterproof wrapping

- Brinell Hardness

- 95 HB (T6)

- Melting Point

- 582 - 652°C

- Thermal Conductivity

- 167 W/mK

- Elongation

- 10-18% (depending on temper and thickness)

- Machinability

- Very Good

- Tolerance

- As per international standards

- Formability

- Good, especially in O temper

- Density

- 2.70 g/cm³

- Weldability

- Excellent, suitable for TIG/MIG welding

About Aluminium 6061 Sheet / Plate / Coil

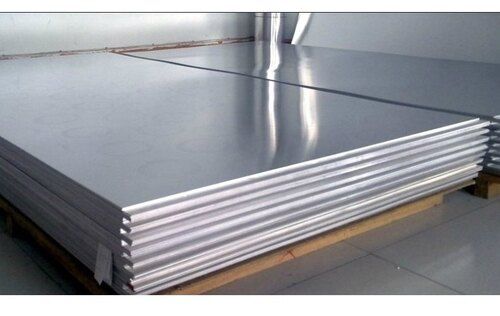

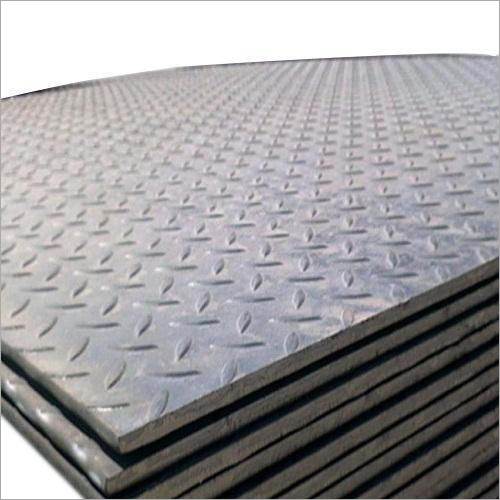

Aluminum Alloy 6061 Hot Rolled Plate , Aluminium 6061 Chequered Plates, UNS A96061 Plates, ASME SB 209 Aluminium 6061 Plates, Aluminium 6061 Plates Stockist in Mumbai, India.Aluminium 6061 CR Plate, Aluminium 6061 Industrial Plates, Aluminium 6061 Sheet, Aluminium 6061 Cold Rolled Plate, Aluminium 6061 Plates Supplier in Mumbai, India.Specification of Aluminium Alloy 6061 PlatesSpecifications: ASTM B209 / ASME SB209

Temper: O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851

Thickness: 0.2300mm

Width: 5002500mm

Length: 50010000mm

Surface: Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc.

Finish: Mill, Customer specific finish

Aluminum Sheet/ Plate Coating: PVC Coated, Color Coated, Polyester, Fluorocarbon, polyurethane and epoxy coating

Type: Hot-Rolled (HR) / Cold-Rolled (CR) Sheet / Plates/ Strips/ Coils / Chequered Plates

Aluminium 6061 Plates Equivalent GradesVersatility in Applications

Aluminium 6061 sheets, plates, and coils are commonly utilized in industries such as automotive, aerospace, marine, transport, and construction due to their strong mechanical properties and resistance to corrosion. Their adaptability allows for use in structural components, fabrication projects, and custom engineering solutions.

Customizable Dimensions and Surface Treatments

Aluminium 6061 products are available in various thicknesses (0.5 mm to 150 mm), lengths (standard or up to 6000 mm+), and widths (1000 mm, 1250 mm, 1500 mm, or custom). The surfaces can be supplied in mill finish, anodized, or brushed, catering to diverse aesthetic and functional requirements.

Excellent Weldability and Machinability

Offering excellent TIG and MIG weldability, Aluminium 6061 is ideal for both fabrication and repair tasks. Its good machinability ensures efficient processing, making it suitable for precision parts and complex assemblies. The alloy's moderate hardness and ductility facilitate forming and shaping operations.

FAQ's of Aluminium 6061 Sheet / Plate / Coil:

Q: How is Aluminium 6061 Sheet / Plate / Coil typically fabricated?

A: These products are manufactured through cold- or hot-rolling, and sometimes extruded processes. Depending on specifications, fabricators choose temper (T6, T651, O, etc.) and appropriate surface finish (mill, brushed, anodized) to match application needs.Q: What are the main benefits of using Aluminium 6061 in industrial applications?

A: Aluminium 6061 offers medium to high strength, excellent corrosion resistance, lightweight construction, and high weldability, making it ideal for automotive, aerospace, marine, transport, and structural uses. Its machinability ensures ease of manufacturing complex components.Q: When should you choose a specific temper for Aluminium 6061 products?

A: Selection of temper (e.g., T6 for high hardness, O for better formability) depends on desired mechanical properties-greater strength or more ductility-and application requirements such as fabrication method, load conditions, and assembly process.Q: Where are Aluminium 6061 Sheets, Plates, and Coils most commonly used?

A: These products find extensive use in sectors like automotive, aerospace, marine, transport, structural engineering, fabrication shops, and construction due to their reliable performance, flexibility in size, and corrosion resistance.Q: What processes are suitable for joining or welding Aluminium 6061?

A: Aluminium 6061 is best joined using TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding techniques, owing to its excellent weldability. It can also be fastened or riveted depending on design and structural needs.Q: How does Aluminium 6061's corrosion resistance benefit users?

A: The alloy's strong corrosion resistance ensures durability and low maintenance in harsh environments, such as marine and outdoor structural applications, thereby increasing the service life of fabricated components.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminum Plate Category

Aluminium 7075 plates

Price 310 INR / Number

Minimum Order Quantity : 5 Kilograms

Color : Silver

Strength : High

Finish : Smooth

Alloy : AluminiumZinc

Aluminium Plate 7075

Price 310 INR / Number

Minimum Order Quantity : 5 Kilograms

Color : Silver

Strength : High

Finish : Smooth

Alloy : Yes

Aluminium Plate 1200

Price 210 INR / Number

Minimum Order Quantity : 5 Kilograms

Color : Silver

Strength : Moderate

Finish : Plain / Mill Finish

Alloy : 1200

Aluminum Chequered Plate

Price 300.00 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Color : Silver

Strength : MediumHigh

Finish : Polished

Alloy : Aluminium Alloy

GST : 27AALHA0224K1ZI

|

METAL VISION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry