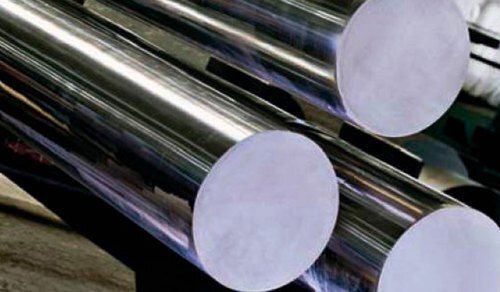

Nickel 201 Round Bar

Price 1000 INR/ Number

Nickel 201 Round Bar Specification

- Product Type

- Nickel 201 Round Bar

- Shape

- Round

- Elongation

- At least 45%

- Strength

- Tensile Strength: 370 MPa

- Hardness

- Brinell: 65 HB

- Resistance

- Excellent resistance to acids, alkalies, and caustic environments

- Grade

- Nickel 201

- Melting Range

- 1435C to 1446C

- Density

- 8.89 Gram per cubic centimeter(g/cm3)

- Chemical Composition

- Nickel (99.96%), Iron (0.2%), Copper (0.01%), Carbon (0.02%), Manganese (0.35%)

- Application

- Chemical processing, food processing, aerospace, electronics, marine, power generation

- Color

- Silver/Grey

- Weldability

- Excellent weldability

- Machinability

- Good machinability

- Conductivity

- High electrical and thermal conductivity

- Finish

- Bright, Polish

- Corrosion Resistance

- Highly resistant to corrosion in neutral and alkaline environments

- Magnetic Properties

- Non-magnetic

- Length

- Custom cut lengths available

- Standards

- ASTM B160 / ASTM B161

- Size Range

- Diameter: 5 mm to 500 mm

- Surface

- Smooth, Free from scales and impurities

About Nickel 201 Round Bar

Nickel 201 Bar, ASTM B160 Nickel 201 Round Bars, Nickel UNS N02201 Bright Bar, 201 Nickel Triangular Bar, Nickel Round Bar, Nickel Alloy 201 Rods Suppliers and Dealer in Mumbai, India. Nickel 201 Round Bar, Suppliers of ASTM B160 Nickel 201 Hex Bar, 201 Nickel Alloy Forged Bars Exporter, Nickel 201 Hexagonal Bar, Nickel 201 Square Bar, Nickel WERKSTOFF NR. 2.4068 Round Bars Manufacturer in India. Specialist Distributor of ASTM B160 Alloy 201 Threaded Bar, Alloy 201 Flat Bar, Hot Rolled Nickel 201 Round Bar, Nickel GOST ????-2 Cold Drawn Round Bar, 201 Nickel Polished Bar,201 Alloy Black Bar Exporter in India.Exceptional Corrosion Resistance

Nickel 201 Round Bar stands out for its remarkable resistance to corrosion, especially in neutral and alkaline environments, as well as in the presence of acids and caustic solutions. This property ensures a long service life and reliable performance in harsh and demanding conditions, making it the preferred choice for chemical processing and other heavy industries.

Versatile Applications Across Industries

Thanks to its unique blend of high purity, strength, and conductivity, Nickel 201 Round Bar finds extensive applications in diverse sectors. From chemical and food processing equipment to components in the aerospace, electronics, marine, and power generation industries, this round bar fulfills various critical roles while maintaining safety and efficiency standards.

FAQ's of Nickel 201 Round Bar:

Q: How does Nickel 201 Round Bar benefit chemical processing applications?

A: Nickel 201 Round Bar offers exceptional resistance to corrosion from both acids and alkalies, making it particularly suitable for chemical processing environments. Its high purity (99.96% nickel) ensures minimal contamination, while its excellent strength and machinability contribute to durable, reliable, and easily fabricated process equipment.Q: What standards govern the quality and composition of Nickel 201 Round Bar?

A: Nickel 201 Round Bar is produced and tested in accordance with ASTM B160 and ASTM B161 standards, which ensure consistent chemical composition, mechanical properties, and high quality. These standards guarantee a product suitable for critical industrial applications worldwide.Q: When should I consider using Nickel 201 Round Bar for my application?

A: You should choose Nickel 201 Round Bar in applications requiring outstanding corrosion resistance, high conductivity, and reliable mechanical strength-particularly in processes involving neutral or alkaline environments, or where parts are exposed to acids and caustics. Its non-magnetic nature also makes it ideal for sensitive electronic and aerospace components.Q: Where can Nickel 201 Round Bar be sourced, and in what sizes?

A: Nickel 201 Round Bar is available globally through various exporters, importers, manufacturers, suppliers, traders, and wholesalers, particularly in India. It can be purchased in diameters ranging from 5 mm to 500 mm, and lengths can be custom cut to meet specific project requirements.Q: What is the typical process for machining and welding Nickel 201 Round Bar?

A: Nickel 201 Round Bar is known for good machinability, allowing for ease of turning, drilling, and shaping with standard tools. It also possesses excellent weldability, accommodating a wide variety of joining methods such as TIG, MIG, and resistance welding, without compromising its corrosion-resistant properties.Q: How is the surface quality of Nickel 201 Round Bar ensured?

A: The bar undergoes bright polishing and finishing processes to achieve a smooth, scale-free, and impurity-free surface. This not only enhances aesthetics, but also improves resistance to contaminants and facilitates better performance in sensitive applications.Q: What are the main benefits of using Nickel 201 Round Bar in marine and power generation industries?

A: In marine and power generation settings, Nickel 201 Round Bar is highly valued for its outstanding resistance to corrosive environments and high thermal conductivity. These attributes help extend equipment lifespan, minimize downtime, and ensure reliable operation under demanding conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Nickel Alloy Products Category

Nimonic 80 Round Bar

Price 2000 INR / Number

Minimum Order Quantity : 5 Kilograms

Grade : Nimonic 80A

Product Type : Other, Nimonic 80 Round Bar

Color : Silver / Metallic

Shape : Other, Round Bar

Nickel Alloy Pipe Alloy-20

Price 2500 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Grade : Alloy 20 (UNS N08020)

Product Type : Other, Nickel Alloy Pipe

Color : Silver/Gray Metallic

Shape : Other, Round/Seamless/Welded Pipe

Nickel 200 Sheet / Plate / Coil

Price 900 INR / Number

Minimum Order Quantity : 5 Kilograms

Grade : Nickel 200

Product Type : Other, Nickel 200 Sheet / Plate / Coil

Color : Silverygrey

Shape : Other, Sheet, Plate, Coil

Alloy Steel ASTM A 320 Studs, Bolts and Rods

Price 48 INR / Number

Minimum Order Quantity : 10 Pieces

Grade : ASTM A320 (Grades: L7, L7M, B8, B8M, etc.)

Product Type : Other, Alloy Steel ASTM A 320 Studs, Bolts and Rods

Color : Metallic Silver/Grey

Shape : Other, Studs, Bolts, Rods (Threaded/Unthreaded)

GST : 27AALHA0224K1ZI

|

METAL VISION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry